we build roofs

About Us

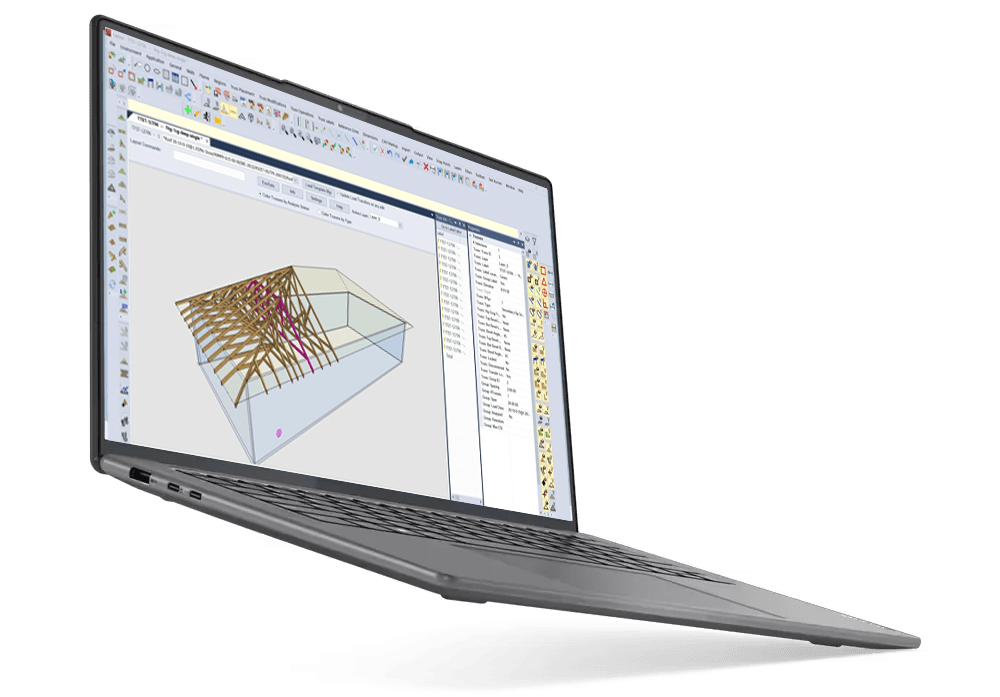

Matlosana Roofing is part of a voluntary group of Independent retailers specializing in truss manufacturing and related roofing hardware. It is a dynamic organization boasting a market leading growth in the design and manufacturing in the roof truss industry.

Maltosana Roofing is situated in Klerksdorp, and supplies roofs all over central South Africa as far as Centurion and Kimberley.

Matlosana Roofing’s target market embraces all activity within the design and manufacturing industry, focusing particularly on the building of basic urban house and the”Township” house roof.

We aim to provide a full solutions to build a roof form the design to the finishes.